“Take advantage of our unique expertise in packaging optimization to make your company more productive, profitable and competitive.”

- Vektor Group team

About us

Stretch-film

Optimization

Vektor Group LLC supplies high-quality stretch-films to consumers in Russian Federation.

Consumers that are using stretch-films supplied by our company, always are convinced of the ultimate quality of our products.

Our aim is not just to supply stretch-films to our customers, but to provide with a full service chain, connected with utilization of this very packaging material.

Our experienced and competent team works out a stretch-film application for every single customer paying attention to all aspects of stretch-film application process: startng with a selection of the stretch-film of required grade, type, thickness, mechanical strength properties to meet the product to be wrapped and finishing with working out a perfect wrapping configuration which will reduce wrapping materials consumption without compromising quality and stability of wrapped loads.

Stretch-film supplied by our company:

- drastically reduces costs for a wrapped unit/load;

- reduces risks of loss or damage of goods during transportation;

- improves safety and integrity of loads/goods when stored;

- reduces time required for wrapping of a single pallet.

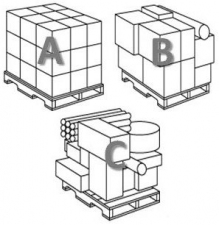

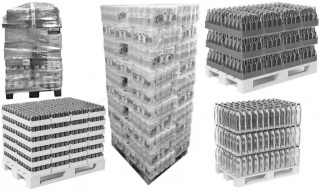

1. Load Size

There are three types of loads:

- Type A: loads of this type are the easiest loads to wrap. They have a uniform shape, size of the load equals size of the pallet. Such loads can be often seen at production sites. Puncture points are rare.

- Type B: loads of this type are less uniform than Type A loads, and they have several film puncture points. Usually each pallet can contain two or three products destined to the same location. The stretch film selection is rather critical and must have high performance features.

- Type C: loads of this type differ a lot one from another. There is a big difference between size of the load and size of the pallet. They have several puncture points. The right stretch film selection is critical.

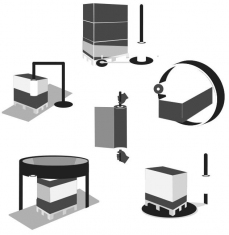

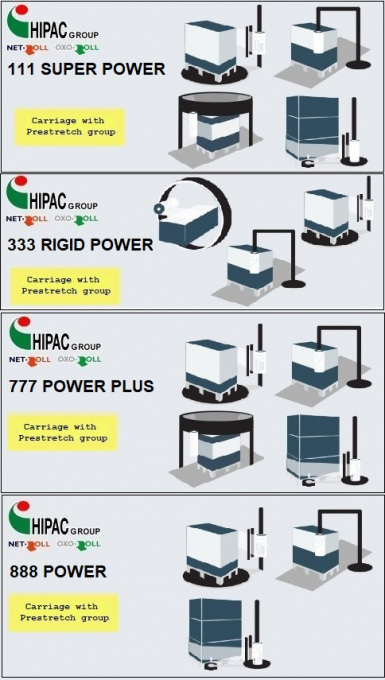

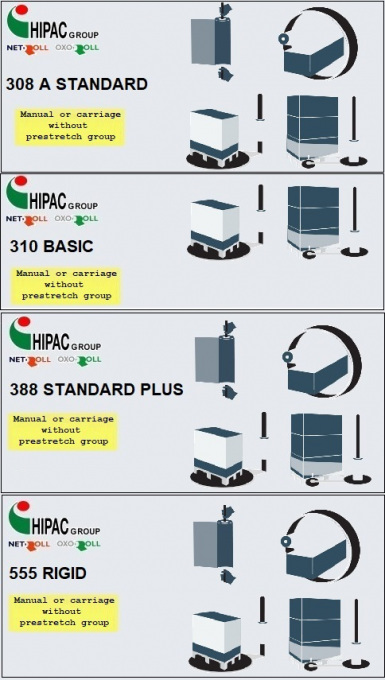

2. Equipment that will be used

To determine which type of stretch film to use you need to consider the type of equipment you are using. Fully automatic stretch film wrapping machines require high performance films, semi-automatic wrapping machines also require a high-performance film, but selection depends of the wrapping machine features and characteristics.

3. Product to be wrapped

While selecting stretch film type, thickness and the number of wraps you need, you have to determine the type of products you are going to wrap and consider the weight of the pallet load.

4. Special Needs

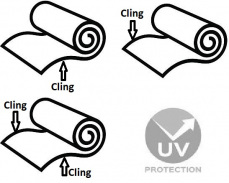

You need to ask the customer if there are special requirements, such as a one side cling or UV protection of the stretch wrap. A one side cling is usually used when the pallet load shift in transit. UV stretch films are used if the goods are stored outside for long periods.

5. Logistics

Finally, you need to consider the distance and mode of transport. It is not the same to deliver goods across the country compared just to move it across the street -- you will require a different stretch film. The distance and mode of shipment are important considerations.

How to choose the appropriate Stretch Film that meets your requirements?

There are five things to take in account for choosing the right stretch film to wrap your loads:

Types of stretch-film we are offering

Stretch-film for hand application

Stretch-film for machine application

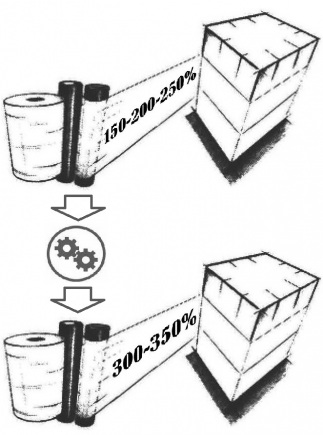

Innovation and optimization are the cornerstones of the Vektor Group stretch wrapping program. By taking a holistic approach to the entire stretch wrapping process from equipment, to film, to application we can create stretch wrapping standards that bring long-term sustainable value and savings.

We can eliminate break, damage and loss and deliver lowest unit cost all day, every day.

For every our customer we develop a system and wrapping solution and one can monitor every single load, wrapped on a certain unit or a specific wrapping line.

When we discuss stretch film applications with a customer where there is an opportunity to upgrade equipment or optimize films, the first thing we do is audit current operations. We want to see how the customer is currently using stretch film – from the products being wrapped, to the loads, the film properties, the amount of film used, the equipment settings, operator consistency, and the overall application. We also discuss any existing problems or concerns as well as the ultimate goals for the packaging operation.

This film audit reveals so much to our engineers and equipment specialists about opportunities where we can possibly downgauge films, use less film, tweak film properties, or adjust equipment settings to better match the application. These kinds of changes result in less material waste and significant cost savings for our customers.

Beyond the initial audit and optimization, we always perform monitoring of equipment, its settings and consumption of stretch film.

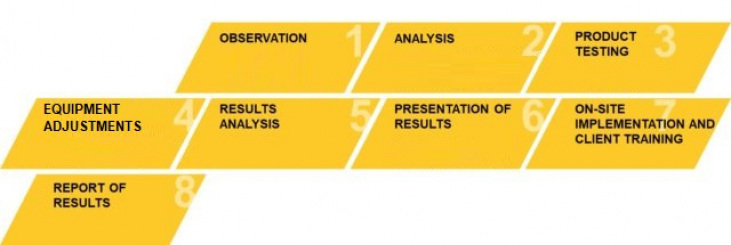

Our method